008613968780263

008613968780263

In the world of thermal management, the choice of cooling solutions can greatly impact performance. One expert, Dr. Sarah Lin, a leading figure in heat transfer technology, states, “Extrusion Heat Sinks are vital for effective thermal management in electronics.” The growing demand for efficient cooling solutions has put Extrusion Heat Sinks at the forefront of design considerations.

Extrusion Heat Sinks are manufactured from materials like aluminum, providing excellent thermal conductivity. These components are tailored to dissipate heat efficiently, which is crucial in today’s compact electronic devices. Many industries rely on these solutions to ensure longevity and reliability. However, one must consider the design and configuration of the heat sinks. Poorly designed geometries can lead to ineffective heat dissipation.

Investing in high-quality Extrusion Heat Sinks may reduce thermal issues, but they are not a silver bullet. Suboptimal placement within a system can negate their benefits. As technologies advance, the need for customizable designs will become even more pertinent. Addressing these challenges is essential for maximizing the effectiveness of Extrusion Heat Sinks in various applications.

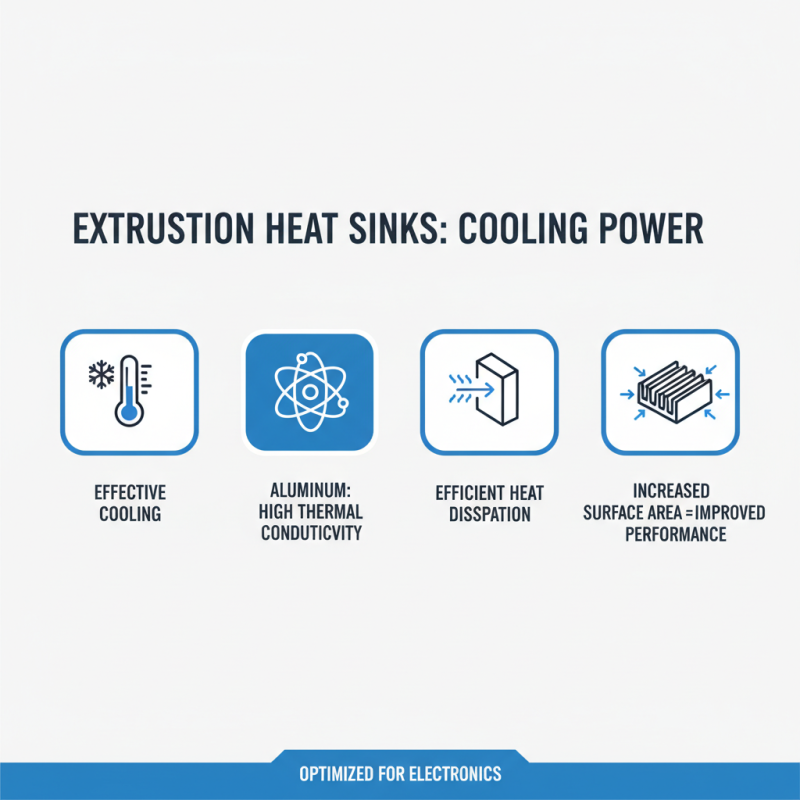

Extrusion heat sinks are essential for effective cooling solutions. They are made from aluminum, which offers excellent thermal conductivity. This material helps dissipate heat from components efficiently. The design of extrusion heat sinks allows for increased surface area. More surface area means better heat dissipation and improved performance.

When selecting an extrusion heat sink, consider the application. Different components generate various heat levels. It’s vital to match the heat sink’s capacity to your needs. Remember that a larger size typically means better cooling. However, space constraints in your design may require a more compact option.

Tips: Always assess the airflow around the heat sink. Adequate airflow enhances cooling efficiency. Restricting airflow can lead to overheating issues. Also, checking the mounting method is essential. A poor fit may reduce contact area and degrade performance. Ensure your heat sink is installed correctly for optimal results.

When it comes to cooling solutions, extrusion heat sinks stand out. They are widely used in electronics due to their efficiency. These heat sinks are made from aluminum, allowing for effective thermal management. Their design promotes better airflow, which enhances cooling performance. The lightweight nature of extruded aluminum also contributes to ease of installation.

One notable advantage of extrusion heat sinks is their ability to be customized. This means they can fit various applications and environments. Custom designs can include unique shapes or multiple fins. This versatility makes them appealing in different industries. However, the manufacturing process does require precise planning, which can complicate production. Sometimes, this leads to excess material or unexpected costs.

Furthermore, the surface treatments on extrusion heat sinks can impact performance. Anodizing can improve corrosion resistance but adds to the cost. There might be trade-offs in choosing the best surface finish. Balancing aesthetics and functionality often poses a challenge. It is essential to weigh these aspects when opting for extrusion heat sinks. They may offer many benefits, but careful consideration is necessary to ensure they meet specific needs.

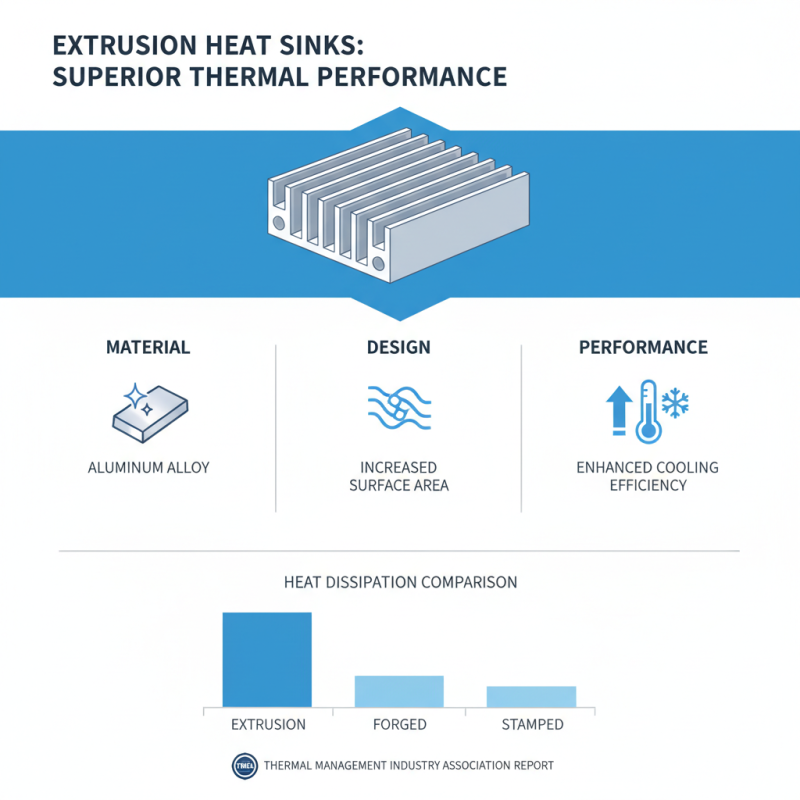

When considering heat sink types, extrusion heat sinks stand out. They are made from aluminum and offer exceptional thermal performance. A report by The Thermal Management Industry Association indicates that extrusion heat sinks can dissipate heat more efficiently than stamped or forged alternatives. Their unique design allows for increased surface area, which enhances cooling capabilities.

Extrusion offers a lightweight solution, making it easier to integrate into various applications. Unlike other heat sink types, extrusions can be designed to fit specific spaces and requirements. In certain situations, non-extrusion options can struggle with weight and thermal transfer efficiency. A study found that extrusion heat sinks reduced thermal resistance by up to 25% compared to those made from copper.

**Tip:** Consider the specific cooling requirements of your project. Weigh the benefits of extrusion heat sinks against potential drawbacks, like cost or availability.

Another key point is the manufacturing process. While extrusion might lead to some material waste, its benefits often outweigh this concern. Proper design can minimize waste and lead to better thermal management. Some may find the initial costs higher than basic options. However, the long-term efficiency and reliability can justify the investment.

**Tip:** Conduct thorough research before selecting a heat sink type. Test different models to see which performs best in your environment.

When selecting extrusion heat sinks for cooling solutions, several factors should be considered. The material choice is crucial.

Aluminum is lightweight and has excellent thermal conductivity. Copper, while heavier and more expensive,

offers superior heat dissipation. Each material has its own pros and cons.

Design is another important factor. The fins’ spacing and height can significantly affect heat transfer efficiency. A denser fin structure maximizes surface area but can trap airflow.

It’s essential to find a balance that enhances performance without compromising airflow.

Tip: Always assess the application’s heat generation. Overestimating or underestimating can lead to inefficiencies.

Consider real-world operating conditions.

Thermal interface materials also play a role. They fill gaps between the heat sink and the component, enhancing thermal conductivity.

Even a small imperfection can reduce performance.

Tip: Regularly check and maintain the heat sink. Dust accumulation can reduce efficiency.

Cleaning ensures optimal airflow and performance.

Selecting the right extrusion heat sink requires careful thought, as each choice impacts overall system performance.

Extrusion heat sinks are increasingly vital across various industries for effective cooling solutions. Their design allows for efficient heat dissipation, essential in electronics, automotive, and renewable energy sectors. In electronics, for instance, nearly 50% of devices have thermal management as a top priority. Heat sinks made from aluminum provide good conductivity, critical for maintaining optimal performance.

In automotive applications, heat sinks support cooling in electric vehicles. Approximately 70% of EV manufacturers now use extrusion heat sinks to manage battery temperatures. This shows a significant move towards using sophisticated cooling methods to enhance efficiency. Likewise, in solar energy systems, these heat sinks help in maximizing the efficiency of photovoltaic cells. Effective cooling can improve energy conversion rates by 20%.