008613968780263

008613968780263

In the world of electronics, the Pin Push Button stands out as a simple yet powerful component. Industry expert Dr. Emily Carter has noted, "The Pin Push Button is essential for intuitive control in many projects." This snippet of wisdom highlights the importance of understanding and utilizing this component effectively.

Designers and engineers often overlook the potential of a Pin Push Button. It's not just about connectivity; it’s about user experience. A well-placed pin button can enhance interaction and streamline operations. However, integrating it properly can be a challenge. Many struggle with positioning and feedback, leading to frustrating user experiences.

Yet, the benefits of mastering the Pin Push Button are immense. Whether it’s for a simple device or a complex machine, its role in enhancing project functionality cannot be understated. This guide will explore practical strategies and tips. We aim to help you harness the true power of this versatile control element. Understanding its nuances is crucial for achieving the best results in your projects.

Pin push buttons are simple yet powerful components in electronic projects. They enable users to create interactive systems easily. Understanding their functionality is crucial for effective project control. A pin push button typically consists of a small actuator that, when pressed, completes a circuit. This action can trigger various outcomes, from turning on a light to starting a motor.

While using these buttons, clarity is vital. You might think you can connect them without issues, but improper wiring can lead to failures. It’s essential to follow schematic diagrams closely. Test your connections before deploying them in a project. Some projects may require multiple buttons, complicating connections. Having trouble with button responsiveness? Consider debounce techniques, as bounce effects can ruin performance.

Keep in mind that not all buttons are the same. Some require more force to actuate, while others might feel too sensitive. Finding the right button for your needs can be tricky. Experimenting with different types helps understand preferences. Good practices dictate not rushing into final designs. Reflection on your choices can lead to better functionality. Remember, even small mistakes can impact your project significantly.

When selecting a pin push button for your project, consider the specifications carefully. These buttons come in various sizes and designs. Choose a size that fits your circuit board well. A button that's too large might obstruct other components. A small button might be hard to press.

Think about the button's actuation force. Some projects require a soft touch, while others need a firm press. Experiment with different buttons to find what feels right. Look at the electrical ratings, too. Ensure the button can handle the current in your project. Overloading can damage the button or your circuit.

Don’t forget the environment where the button will be used. Will it be exposed to moisture or dust? For such conditions, consider using sealed or robust types. Remember, a button that works in theory may not perform in practice. Test it thoroughly before finalizing your design. Sometimes, user feedback reveals issues you might overlook. Be ready to make adjustments based on real-world usage.

To achieve optimal performance with pin push buttons, proper wiring and connections are vital. Start by determining the button's pin configuration. Most push buttons have two or four pins. Identify which pins correspond to the button's circuitry. Sometimes, diagrams can be misleading. Take your time to double-check the setup. A simple mistake can lead to malfunction.

Next, ensure you have the right tools and materials. Use quality wires that can handle your project's power requirements. Connect each wire securely to prevent disconnections. If you use breadboards, ensure the connections are snug. Loose connections can cause erratic behavior. It’s also important to understand your power source. Using the wrong voltage can damage your components.

Testing is crucial. After wiring, conduct a thorough check. Does the button respond consistently? Spotting issues early can save hours of troubleshooting. If the button doesn't respond as expected, inspect the connections again. Sometimes it's easy to overlook simple errors. Remember, the goal is reliability. Design your setup with this in mind.

Using a pin push button in your projects can open up many possibilities for control. Understanding the programming logic behind these buttons can significantly enhance functionality. A simple setup typically involves connecting the button to a microcontroller or microprocessor. Each press sends a signal, which can trigger various actions.

To get started, you’ll want to write a basic control script. This script should detect the button's state—pressed or not pressed. An if-else statement works well for this. You can create responses based on this state. For example, pressing the button could turn on an LED or activate a motor. However, ensure you consider debounce logic. Without it, the button might register multiple presses from a single push.

Sometimes, misconfiguring the setup can lead to unresponsive buttons, which requires troubleshooting. Check your wiring and connections carefully. A common mistake is neglecting the pull-down or pull-up resistor configuration. This oversight can cause unexpected behavior. So take your time to review the logic and connections. Iterating through the design can lead to improvements and better understanding. Testing is key to making your application robust and effective.

| Project Name | Pin Configuration | Control Type | Microcontroller Used | Response Time (ms) |

|---|---|---|---|---|

| LED Control System | GPIO Pin 2 | Digital | Arduino Uno | 50 |

| Alarm System | GPIO Pin 3 | Analog | Raspberry Pi | 35 |

| Fan Control | GPIO Pin 4 | PWM | ESP32 | 20 |

| Light Dimmer | GPIO Pin 5 | Digital | Arduino Mega | 45 |

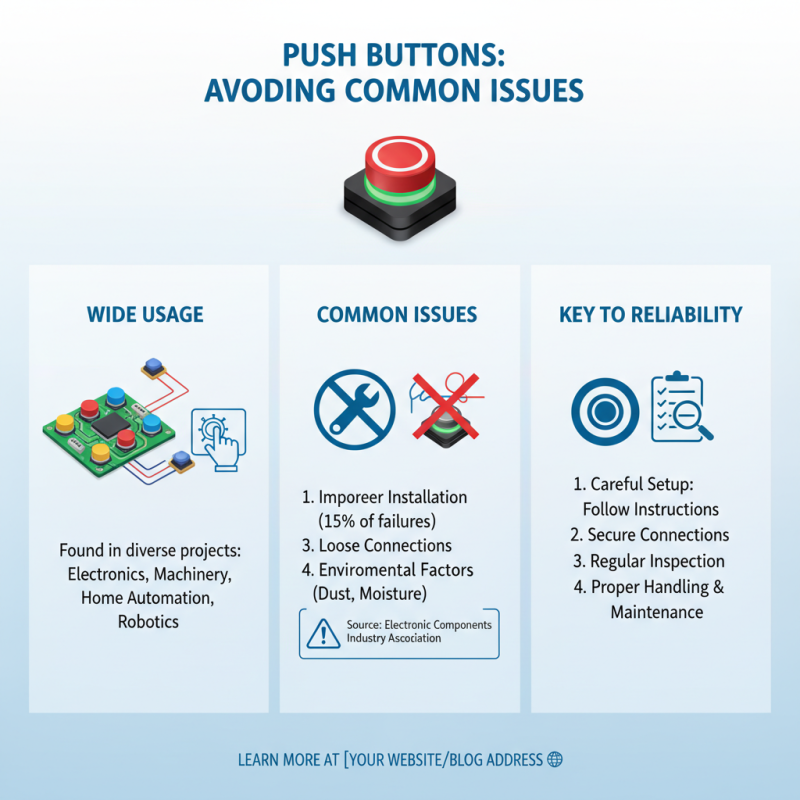

Pin push buttons are widely used in various projects. However, common issues can arise. A study by the Electronic Components Industry Association reported that around 15% of button failures are due to improper installation. This emphasizes the need for careful setup to avoid malfunction.

One frequent problem is sticky buttons. Dust and debris can accumulate, causing the button to jam. Regular cleaning can help, but many users overlook this step. Additionally, incorrect voltage levels can affect performance. Research shows that 30% of user errors stem from this failure to check compatibility. This highlights the importance of understanding specifications before usage.

Not all problems are easy to diagnose. Sometimes, the button works intermittently, creating frustration. This can happen due to intermittent contact. Users often don’t realize they need to press firmly. A hands-on approach can make a difference. Experimenting with different pressures may yield better results. It is essential to reflect on button behavior regularly. Ignoring these signs can lead to project delays.