008613968780263

008613968780263

News

News Categories

Featured News

0102030405

Custom Heatsink Shapes: Unlocking New Possibilities in Heat Dissipation

2025-11-10

Faced with the various limitations of traditional heatsinks, our custom-shaped heatsinks (Custom Heatsink Shapes)have emerged as a new solution, bringing a revolutionary approach to the field of heat dissipation. With innovative design concepts and advanced manufacturing processes, they break the boundaries of traditional heat dissipation and provide more efficient and precise heat dissipation protection for various electronic products.

(1) Custom Shapes to Meet Diverse Needs

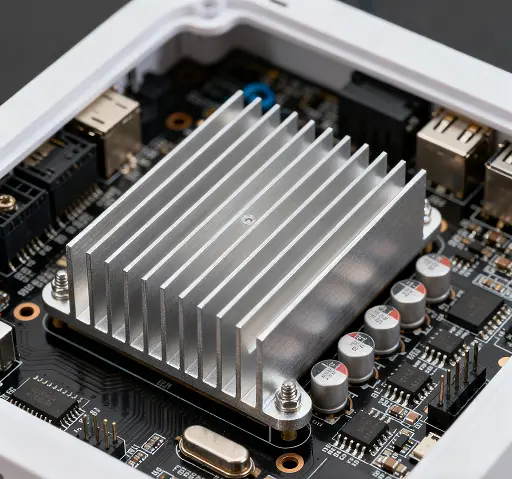

Our custom-shaped heatsinks can be tailored to the unique internal structures and heat dissipation requirements of different electronic products, achieving a perfect fit with heat sources. Taking computer CPUs as an example, their heat-generating areas usually have complex shapes. Traditional heatsinks with fixed shapes cannot fully cover these areas, resulting in low heat dissipation efficiency. Through precise measurement and analysis of CPU heat-generating areas, our custom-shaped heatsinks adopt special-shaped customization to closely fit every heat-generating part of the CPU. This ensures that heat is quickly and evenly transferred to the heatsink surface, significantly improving heat dissipation efficiency. In practical applications with a high-performance computer host, the CPU temperature under high load was reduced by approximately 15℃ after using our custom-shaped heatsink compared to traditional heatsinks. This effectively enhanced the computer's performance stability and reduced issues such as crashes and lagging caused by overheating.

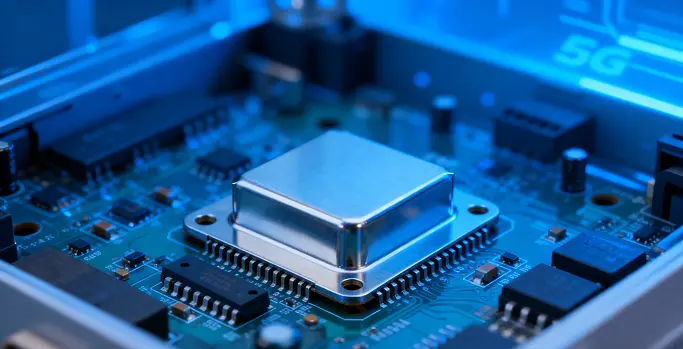

In communication base stations, limited internal space and irregular distribution of heat-generating modules impose strict requirements on the shape and size of heatsinks. The custom heatsinks we developed for communication base stations fully consider the internal spatial layout and heat generation characteristics of the equipment. Adopting an ultra-thin, special-shaped design, they cleverly avoid other components to achieve efficient heat dissipation in confined spaces. These custom-shaped heatsinks not only meet the strict heat dissipation performance requirements of communication base stations but also improve equipment integration and reduce overall power consumption.

(2) Innovative Design to Optimize Heat Dissipation Performance

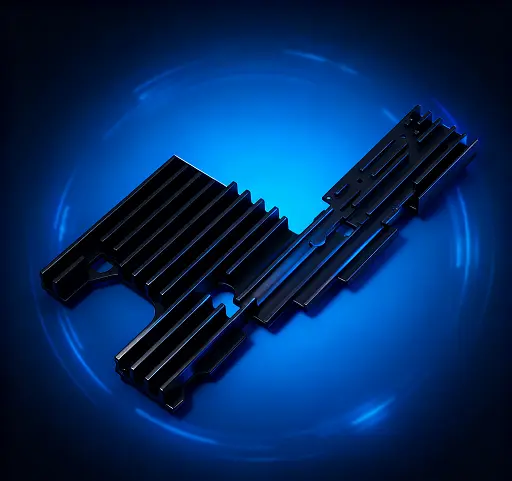

In addition to precisely matching the needs of different electronic products, our custom-shaped heatsinks have been fully optimized for heat dissipation performance. Through innovative shape design, the paths of heat conduction and convection are effectively improved, greatly enhancing heat dissipation efficiency. For example, the special fin shapes we designed can increase the heat dissipation area and promote air convection, allowing heat to dissipate more quickly into the surrounding environment. In some industrial automation equipment, custom heatsinks with special wave-shaped fins are used. Compared to traditional straight fins, these wave-shaped fins increase the heat dissipation area by more than 30%. At the same time, during air flow, they can form more turbulent flow, enhancing the heat exchange efficiency between air and fins. Experimental data shows that after adopting this custom heatsink, the temperature of key components in industrial automation equipment decreased by 10-12℃, significantly improving the operational stability and reliability of the equipment.

We have also innovated in the structural design of heatsinks, adopting a multi-channel, layered design concept to further optimize heat conduction paths. For some high-end servers, which have high heat generation power and strict requirements for heat dissipation uniformity, the custom multi-channel heatsinks we developed can quickly guide heat from different heat-generating areas to various heat dissipation channels. This achieves heat dispersion and uniform transfer, effectively avoiding local overheating. This innovative design ensures that the temperature of each component of the server remains within a reasonable range during long-term high-load operation, guaranteeing stable server operation and improving the efficiency and accuracy of data processing.

Exquisite Craftsmanship, Quality Assurance

(1) Advanced Manufacturing Processes

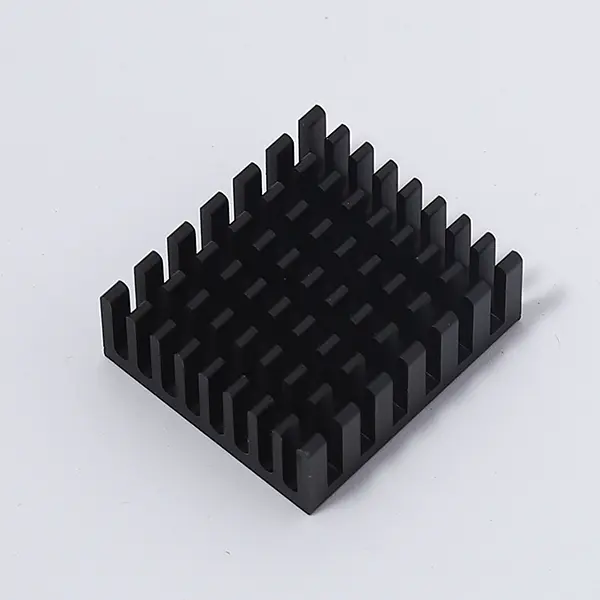

We adopt advanced manufacturing processes to create custom-shaped heatsinks, ensuring every detail meets the highest standards. Precision die-casting is one of our core technologies. By injecting molten metal into mold cavities under high pressure, we can produce heatsinks with complex geometric shapes. This process not only achieves high-precision molding to ensure the heatsink shape is fully consistent with design drawings but also guarantees product structural strength and density. During die-casting, we strictly control parameters such as temperature, pressure, and time to avoid defects such as air holes and shrinkage cavities, thereby improving product quality and reliability. For example, for some custom heatsinks with fine fin structures, precision die-casting can accurately shape the fin shapes and spacing, making air circulation between fins smoother and enhancing heat dissipation effects.

(2) Strict Quality Inspection

To ensure every custom-shaped heatsink delivers outstanding performance, we have established a rigorous quality inspection system. Every link from raw material procurement to finished product delivery is strictly controlled. During raw material procurement, we conduct strict quality inspections on each batch of materials to ensure they meet our high standards. We test the chemical composition and physical properties of materials—such as thermal conductivity and density—to guarantee material quality and performance. Only materials that pass inspection enter the production process, ensuring product quality from the source.

During production, we set up multiple quality inspection procedures to conduct real-time monitoring of each production link. After die-casting, we inspect the heatsink's appearance for surface defects such as sand holes and cracks. At the same time, we use professional measuring equipment to accurately measure the heatsink's dimensions to ensure compliance with design requirements. During 3D printing, we monitor the printing process through software to promptly identify and resolve potential issues such as printing deviations and uneven material accumulation. For key processes such as welding, we perform non-destructive testing—such as ultrasonic flaw detection and X-ray flaw detection—to ensure reliable welding quality.

Before factory delivery, every heatsink undergoes comprehensive performance testing. We simulate actual operating environments to test heat dissipation performance, measuring temperature distribution and heat dissipation efficiency under different working conditions. We also conduct durability tests to simulate performance changes during long-term use, ensuring stable operation within the specified service life. Only products that pass all tests receive our brand logo and are delivered to customers. This strict quality inspection system ensures our custom-shaped heatsinks have excellent quality and reliability in the market, earning high trust and praise from customers.

Inquiry Now to Start a New Heat Dissipation Experience

If you are troubled by heat dissipation issues in electronic products or interested in our custom-shaped heatsinks (Custom Heatsink Shapes), please feel free to contact us at any time. We look forward to cooperating with you to jointly solve heat dissipation challenges and provide you with the highest quality heat dissipation solutions.

Choosing our custom-shaped heatsinks means choosing an efficient, precise, and reliable heat dissipation solution. Let us join hands to start a new heat dissipation experience, protect your electronic products, and help you stand out in the fierce market competition!