008613968780263

008613968780263 Die Casting Heat Sinks: Paving the Way for Advanced Thermal Management

The Intricate Die - Casting Process Unveiled

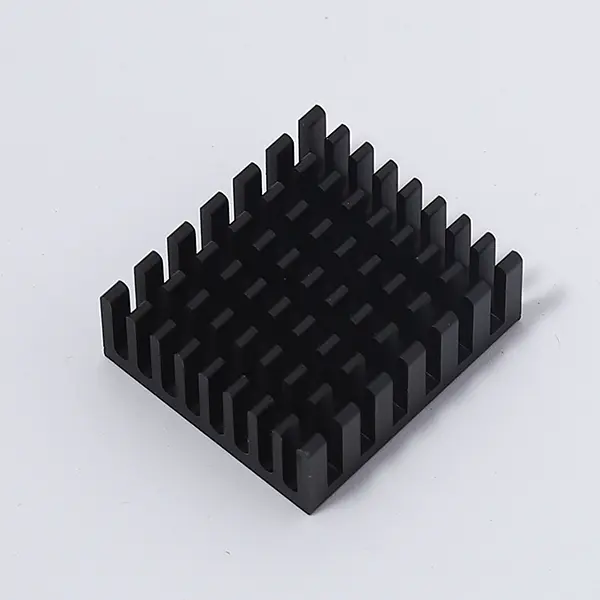

At the heart of die casting heat sinks lies a sophisticated manufacturing process that combines precision and efficiency. Molten metals, with aluminum being the most prevalent due to its favorable properties, are forcefully injected into intricately designed molds under high pressure. This high - pressure injection is a game - changer, as it enables the molten metal to infiltrate every nook and cranny of the mold, giving rise to heat sinks with highly complex geometries. The result is a near - net - shaped product that requires minimal post - processing, slashing production time and costs significantly. This process not only ensures dimensional accuracy but also allows for the creation of features such as fins with varying shapes, sizes, and densities, which are crucial for maximizing heat dissipation.

Unrivaled Advantages of Die Casting Heat Sinks

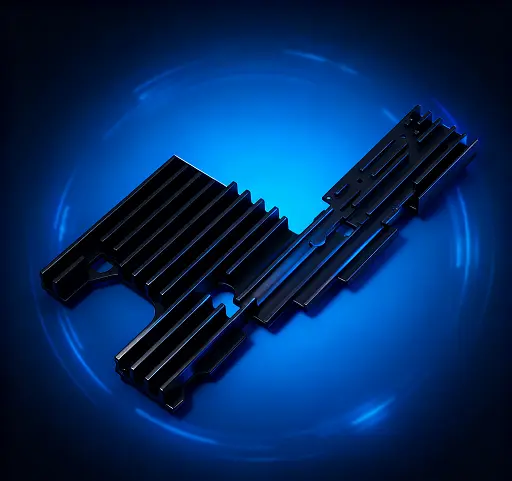

Geometric Complexity Redefined

The ability to produce heat sinks with complex geometries is one of the most compelling advantages of die casting. In today's compact and highly integrated electronic devices, heat sinks need to be tailored to fit within tight spaces while still delivering exceptional thermal performance. Die casting allows for the creation of fin designs that are optimized for specific applications. For instance, in the case of miniaturized electronics like wearables, heat sinks with thin, closely - spaced fins can be die - cast to provide a large surface area for heat transfer in a minute footprint. Additionally, the flexibility in design extends to the creation of unique fin patterns, such as curved or angled fins, which can enhance air flow and convection, further improving heat dissipation efficiency.

Scalability for High - Volume Demands

In industries where mass production is the norm, die casting heat sinks prove to be an invaluable asset. Once the initial investment in mold creation is made, the die - casting process can be seamlessly automated. This automation enables the rapid and consistent production of a vast number of heat sinks. In the electronics industry, where millions of devices are manufactured annually, die casting offers a cost - effective solution. The high precision and repeatability of the process ensure that each heat sink meets the exacting standards required for reliable thermal management. Whether it's for cooling CPUs in personal computers or power modules in industrial equipment, die casting can efficiently meet the high - volume demands of these industries.

Superior Thermal Performance

The materials utilized in die casting, especially aluminum, endow heat sinks with excellent thermal conductivity. The well - engineered fin structures of die - cast heat sinks are designed to maximize the surface area available for heat transfer. Heat generated by electronic components is quickly conducted through the heat sink and dissipated into the surrounding environment. In applications such as high - performance computing, where CPUs and GPUs generate substantial amounts of heat, die - cast heat sinks play a pivotal role in maintaining optimal operating temperatures. The efficient heat dissipation not only prevents component overheating but also enhances the overall stability and performance of the system, reducing the risk of thermal throttling and potential hardware failures.

Diverse Applications Across Multiple Industries

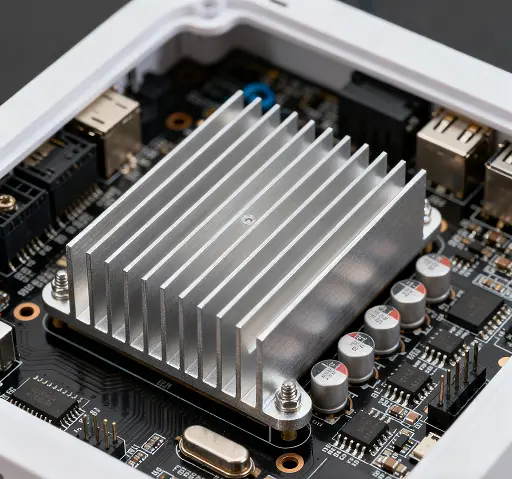

Electronics: The Backbone of Modern Devices

In the electronics industry, die casting heat sinks are omnipresent. In personal computers, they are essential for cooling the CPU, GPU, and power supply units. As processors continue to become more powerful and energy - efficient, the heat they generate remains a challenge. Die - cast heat sinks with their advanced fin designs and high - quality materials are up to the task, ensuring that these critical components operate within their safe temperature ranges. In mobile devices like smartphones and tablets, space is at a premium. Compact die - cast heat sinks are engineered to fit into the limited internal space while effectively dissipating the heat generated by the high - power processors and other components. This helps to improve the device's performance, prevent battery degradation due to overheating, and extend its overall lifespan. Additionally, in LED lighting fixtures, die - cast heat sinks are crucial for maintaining the brightness and longevity of the LEDs by efficiently removing the heat generated during operation.

Automotive: Driving Innovation in Thermal Management

The automotive industry has witnessed a significant transformation in recent years, with the rise of electric vehicles (EVs) and the increasing complexity of automotive electronics. Die casting heat sinks are integral to the thermal management of various automotive systems. In EVs, the battery management system and power inverters generate a substantial amount of heat during operation. Die - cast heat sinks are used to cool these components, ensuring their reliable performance and safety. In hybrid and internal combustion engine vehicles, they are also employed to cool engine control units (ECUs) and other electronic modules. As automotive technology continues to advance, with the introduction of autonomous driving features and more powerful in - vehicle infotainment systems, the demand for efficient thermal management solutions like die - cast heat sinks will only increase.

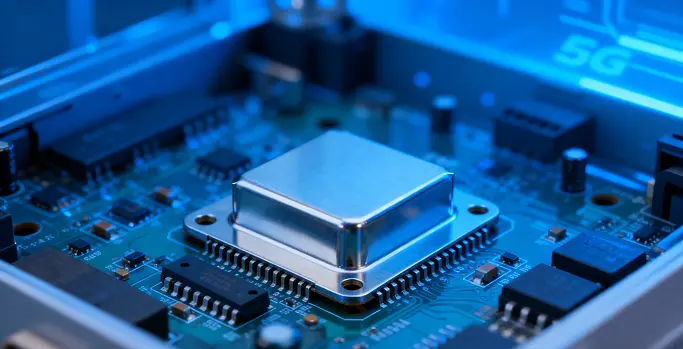

Telecommunications: Enabling the Digital Revolution

With the advent of 5G technology and the continuous expansion of mobile networks, the telecommunications industry is experiencing a boom in data traffic. This growth has led to a corresponding increase in the heat generated by network equipment such as base stations and high - power transmitters. Die - cast heat sinks are well - suited to meet the thermal management challenges in this industry. Their ability to handle high heat loads in a compact form factor makes them ideal for cooling the equipment in base stations, which are often located in space - constrained environments. By efficiently dissipating heat, die - cast heat sinks help to ensure the stable operation of telecommunications equipment, minimizing downtime and maintaining high - speed data transfer capabilities.

The Future of Die Casting Heat Sinks: Innovations on the Horizon

As technology continues to push the boundaries of what is possible, die casting heat sinks are also evolving. Researchers and manufacturers are exploring new materials and manufacturing techniques to further enhance their performance. For example, the development of advanced alloys with even higher thermal conductivity and improved mechanical properties holds great promise. Additionally, the integration of innovative cooling technologies such as phase - change materials and micro - channel cooling within die - cast heat sinks is being investigated. These advancements are expected to revolutionize thermal management, enabling the development of smaller, more powerful, and energy - efficient devices across all industries.

In conclusion, die casting heat sinks have firmly established themselves as a versatile and indispensable solution for thermal management. Their unique combination of complex design capabilities, high - volume production potential, and superior thermal performance makes them a cornerstone of modern technology. As we look to the future, the continued innovation in die - casting technology will undoubtedly play a crucial role in enabling the next generation of advanced electronic, automotive, and telecommunications systems.