008613968780263

008613968780263 0102030405

Heat-Dissipating Aluminum Sheets: An Ideal Choice for Efficient Heat Dissipation

2025-07-09

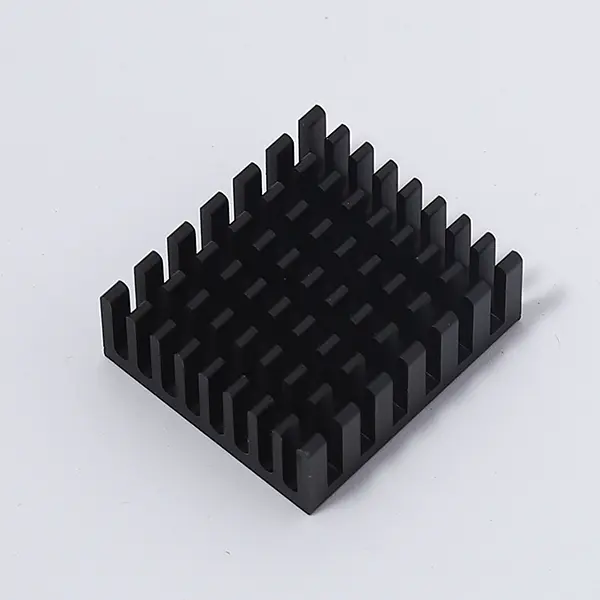

Heat-dissipating aluminum sheets are indispensable heat-dissipating materials in modern industry. Relying on the unique properties of aluminum alloys, they play a crucial role in numerous fields. Their core advantage lies in precise material proportioning. Commonly used aluminum alloy grades such as 1050 and 6061 have their own focuses. 1050 aluminum has high purity with a thermal conductivity of over 220W/(m·K), making it suitable for precision electronic equipment with extremely high requirements for heat dissipation efficiency; 6061 enhances its strength by adding magnesium and silicon elements, with a thermal conductivity of about 160W/(m·K), and is more suitable for industrial scenarios that need to take into account structural support.

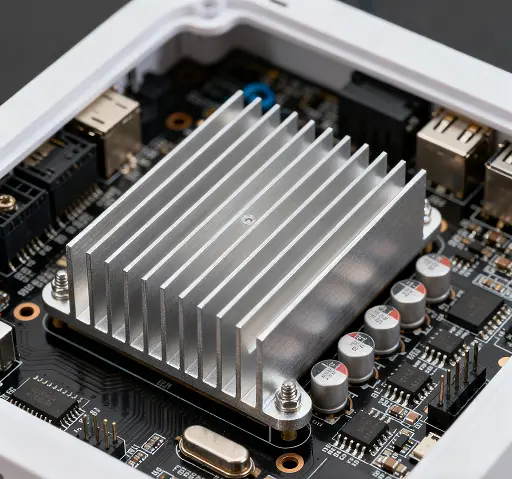

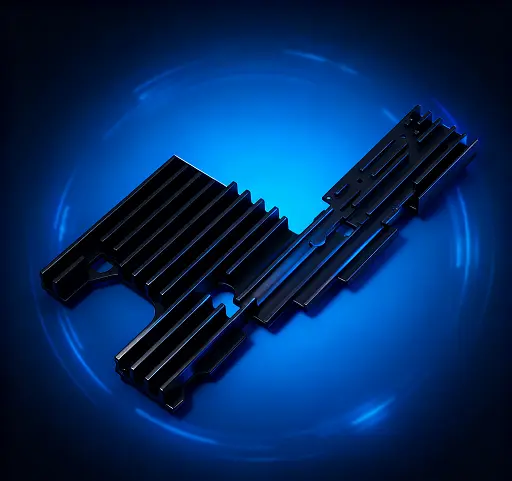

In terms of processing technology, heat-dissipating aluminum sheets integrate a variety of precision technologies. In addition to conventional cutting and stamping, the fin forming process forms dense heat-dissipating teeth through mechanical stretching or welding, increasing the heat dissipation efficiency per unit area by more than 30%; anodizing treatment forms an oxide film of 5-20μm, which not only enhances wear resistance but also strengthens the heat radiation capacity through the porous structure, and can also give various appearances. For special scenarios, electrophoresis coating or chemical conversion treatment can be carried out to improve corrosion resistance and meet the needs of outdoor and humid environments.

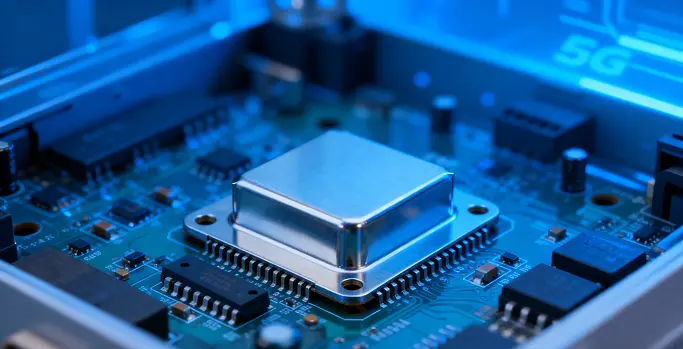

In terms of application scenarios, heat-dissipating aluminum sheets have extremely wide adaptability. In the field of consumer electronics, the ultra-thin design (with a thickness of up to 0.3mm) fits the surface of the chip, quickly dissipating heat for 5G base station power amplifiers and laptop CPUs; in new energy vehicles, the heat-dissipating aluminum sheet at the bottom of the battery pack cooperates with the water cooling system to control the temperature of the battery cells within the ideal range of 25-40℃, ensuring battery life and safety; in industrial equipment, the heat-dissipating modules combining thick plates (5-20mm) and fins can cope with the continuous high-temperature output of high-frequency motors and laser cutting machines. Custom services can process special structures such as irregular shapes and curved surfaces according to the 3D model of the equipment, ensuring a perfect fit with the heat-dissipating components and avoiding the increase in thermal resistance caused by assembly gaps.

Compared with copper heat-dissipating parts, heat-dissipating aluminum sheets are more than 40% lighter in weight and about 50% lower in cost. Moreover, through reasonable design, they can achieve a heat dissipation effect close to that of copper heat-dissipating parts, making them an ideal choice that combines economy and practicality.