008613968780263

008613968780263 Pin Header: A Key Component in the Field of Electronic Connections

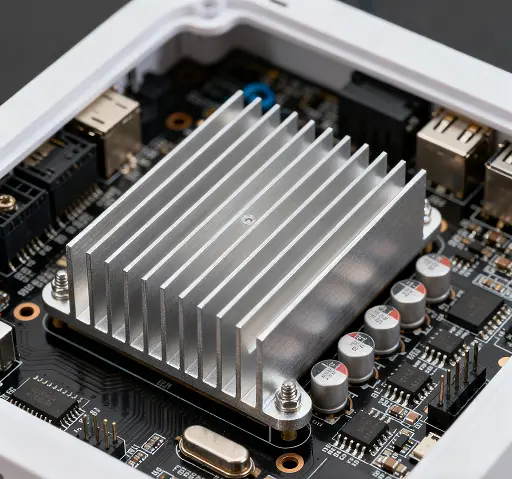

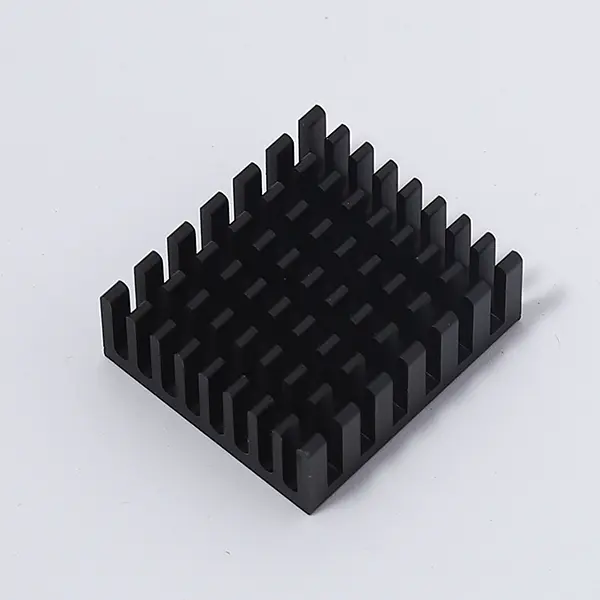

Pin Header (pin header connector) is a core component for realizing signal and power transmission in electronic devices, and has become a "neural node" of circuit connections with its precise design. Its structure consists of a high-strength insulating base and highly conductive metal pins. The base is mostly made of high-temperature resistant nylon or PBT materials, which can withstand welding temperatures above 260°C, ensuring no deformation during the reflow soldering process; the metal pins are made of brass or phosphor bronze as the base material, and after tin plating and gold plating, the coating thickness reaches 3-5μm, which has both excellent conductivity and corrosion resistance. The plug-in life can reach more than 500 times, ensuring long-term stable operation.

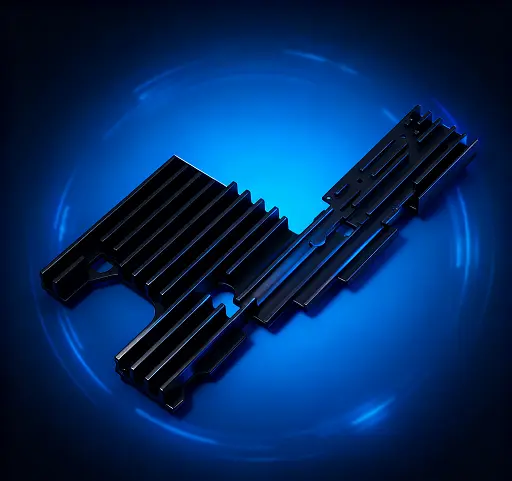

Product specifications are flexible and diverse. According to the number of rows, they can be divided into single-row, double-row and multi-row. The pitches cover common specifications such as 2.54mm, 2.0mm, and 1.27mm. Among them, the 1.27mm ultra-fine pitch models have been widely used in microelectronic products such as wearable devices; the number of pins ranges from 2 to hundreds, adapting to the needs of different circuit densities. There are two installation methods: through-hole and surface mount. The right-angle and vertical direction designs provide more options for circuit board layout. Some high-end models have a shield structure that can prevent wrong insertion and protect the pins. Combined with the positioning column design, the installation error can be controlled within ±0.1mm.

In application scenarios, Pin Header connectors are everywhere. In the consumer electronics field, the signal transmission between the smartphone motherboard and the camera module, and the power distribution of the laptop battery interface all rely on it; in industrial control, the analog signal transmission between sensors and PLC modules, and the drive circuit connection of servo motors are inseparable from it; in medical equipment, the high-voltage power interface of CT machines and the vital sign signal transmission lines of monitors also need its support; in automotive electronics, the GPS signal interface of car navigation and the battery detection lines of new energy vehicle BMS systems also have its presence.

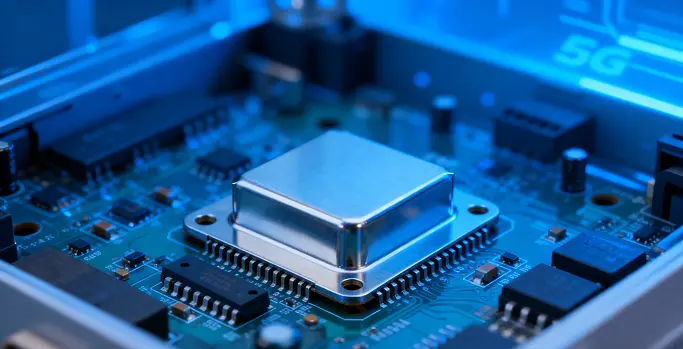

With the development of 5G, new energy vehicles and other industries, the market's performance requirements for Pin Header are constantly increasing, and smaller size and higher integration have become trends. At present, there are models with integrated EMI shielding layers in the industry, which can reduce signal interference by more than 30%. Domestic enterprises such as Changjiang Connector are accelerating domestic substitution, and their independently developed high-temperature resistant models have passed the automotive-grade AEC-Q200 certification; international giants are also continuing technological innovation, launching new models that support 10Gbps high-speed transmission. In the future, this "small part" will play a more critical role in the upgrading of the electronics industry.