008613968780263

008613968780263 0102030405

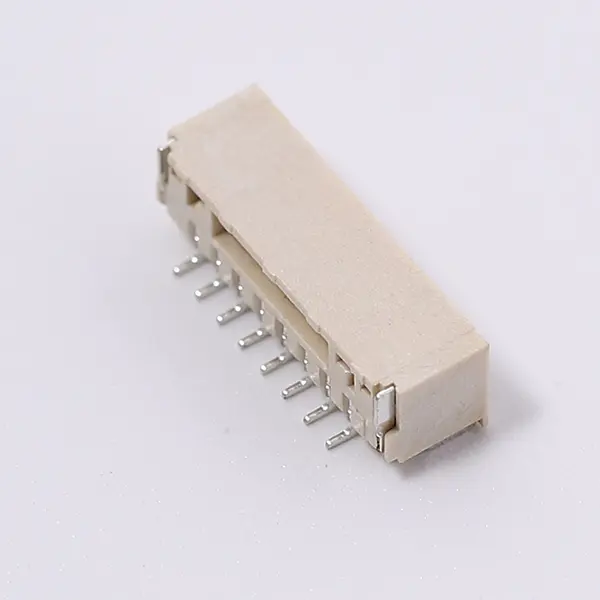

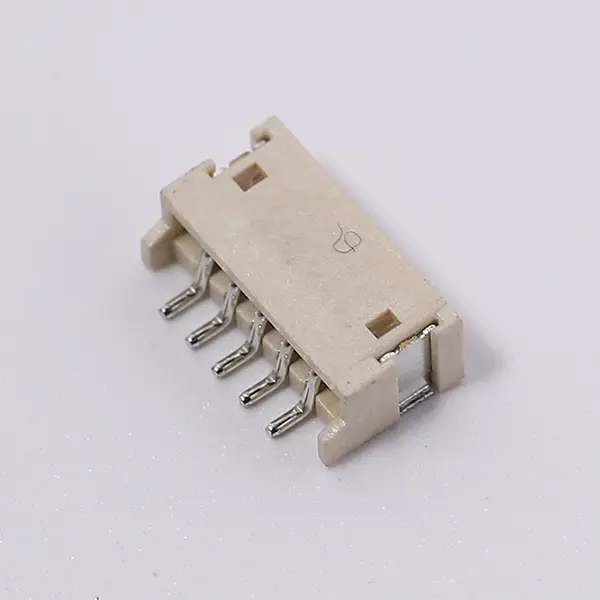

Straight Pin Header: A Reliable Choice in the Field of Precision Connection

2025-11-05

From the perspective of product structure, the high-quality Straight Pin Headers we supply are all composed of highly conductive pins and bases with excellent insulation performance. The pins are carefully made of brass or phosphor bronze, and their surfaces are gold-plated, tin-plated, or nickel-plated according to customer needs: the gold-plated version can significantly improve oxidation resistance and plug-in service life, which we often recommend to customers in high-frequency use scenarios such as medical equipment; the tin-plated version achieves a balance between cost and conductivity, making it a popular choice for us when serving customers in the household appliance industry. The bases are uniformly made of PA66 nylon or PBT engineering plastic, which have the characteristics of high temperature resistance and corrosion resistance. They can maintain structural stability in extreme environments ranging from -40℃ to 125℃, fully meeting the usage needs in harsh scenarios such as automobile engine compartments and industrial control cabinets. This is also our basic guarantee for product quality.

In practical applications, the multi-dimensional adaptability of Straight Pin Header is the core advantage for us to serve customers in different industries. Its pin pitches cover multiple standard specifications such as 2.54mm, 1.27mm, and 0.8mm. We will recommend the most suitable model to customers based on the wiring density of their circuit boards: the 2.54mm pitch version is easy to install, and we often supply it as a supporting product to customers of open-source hardware such as Arduino development boards; the micro-sized version with a pitch of 1.27mm or less can meet the space requirements of miniaturized products such as smartphones and smart wearable devices, and it is our key recommendation for customers in the consumer electronics industry. In addition, the number of pins can range from 2Pin to 64Pin or even more, supporting both single-row and double-row arrangement methods. Whether customers need simple power connection or complex multi-channel signal transmission, we can provide a Straight Pin Header solution with precise matching.

It is worth noting that every batch of Straight Pin Headers we produce undergoes strict quality testing, including insertion and extraction force testing (to ensure that the force for each plug-in is stably within the range of 50-300g), insulation resistance testing (the resistance value must be ≥100MΩ), and high-temperature resistance testing. This prevents problems such as poor contact and pin bending of the products during long-term use from the source. At present, our Straight Pin Headers have been widely used in scenarios such as sensor connection in smart homes, PLC equipment interfaces in industrial automation, and instrument panel circuits in automotive electronics. They have become key components for many customers to achieve stable connection in electronic devices, which also reflects customers' trust in our products.

For customers with customized needs, we can provide more personalized Straight Pin Header solutions. For example, we can adjust the base height according to the customers' special size requirements and optimize the pin plating material for high-frequency transmission scenarios, further meeting the differentiated needs of different industries. Whether it is standardized bulk procurement or customized development, theStraight Pin Headers we supply will provide solid guarantees for the connection systems of customers' electronic devices with their high reliability and strong adaptability. This is also our core service commitment as a supplier.