008613968780263

008613968780263 0102030405

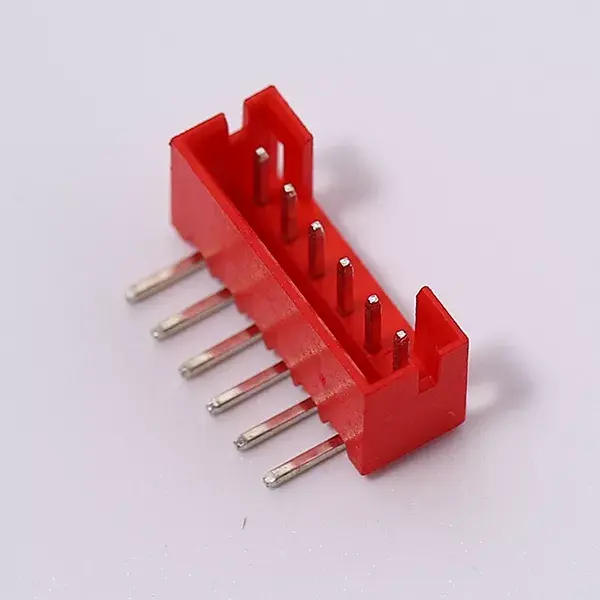

Terminal Strip: The Core Hub for Electronic System Connections

2025-10-24

In the complex structure of electronic devices, the Terminal Strip may seem small—but it acts as an "invisible bridge" that ensures stable signal and power transmission. As an indispensable connecting component in the electronics industry, it enables reliable connections between wires and devices (and between wires themselves) through a standardized wiring structure. Used widely in industrial control, smart homes, automotive electronics, and communication equipment, it has become a key part of boosting system safety and maintenance efficiency.

Terminal Strips can be split into multiple types based on how they connect and where they’re used:

- Screw-type Terminal Strips: Their secure threaded design makes them ideal for high-current, high-vibration industrial settings (e.g., machine tool control cabinets, power distribution boxes). Made with copper alloy contacts, they offer excellent electrical conductivity and corrosion resistance.

- Spring-type Terminal Strips: These use spring elasticity to clamp wires tightly, allowing tool-free, quick wiring. This makes them perfect for smart home panels and small electronic devices, cutting down installation time significantly.

- PCB Terminal Strips: Designed specifically for high-density wiring, these are soldered directly onto circuit boards. They save space in precision systems like communication base stations and medical equipment.

All Terminal Strip types meet international electrical standards, ensuring compatibility and safety across different scenarios.

The value of Terminal Strips goes far beyond just "connecting."

- Their partitioned wiring design keeps wires from different circuits separate, effectively preventing signal interference—a must for sensor signal transmission in automated control systems.

- Some high-end models also include fuse protection and anti-misinsertion features. If a circuit is overloaded, the built-in fuse quickly cuts off current to protect core components from damage.

- Their modular design simplifies maintenance, too: technicians don’t need to take apart the entire device—they only need to inspect or replace specific terminals, which lowers operation and maintenance costs noticeably.

As the electronics industry shifts toward smarter, smaller devices, Terminal Strips are evolving too. Modern models use:

- High-temperature-resistant nylon housings and high-conductivity gold-plated contacts for better durability and performance.

- Digital design to fit the wiring needs of IoT devices, with support for real-time current monitoring.

In new energy vehicles, customized high-voltage Terminal Strips have even become core links between battery packs and electronic control systems—their insulation and anti-aging capabilities directly impact overall vehicle safety.

Though often overlooked, Terminal Strips are the "neural nodes" of electronic systems, supporting the smooth operation of all kinds of devices with their stability and efficiency. As technology keeps advancing, they will continue to evolve, providing an even stronger foundation for connections in the electronics industry.