008613968780263

008613968780263

0102030405

P-1418-C

01

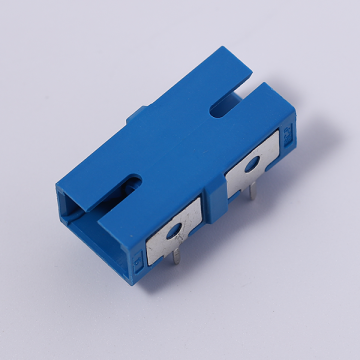

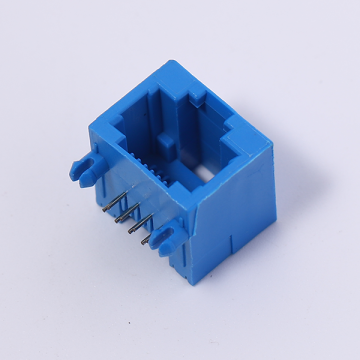

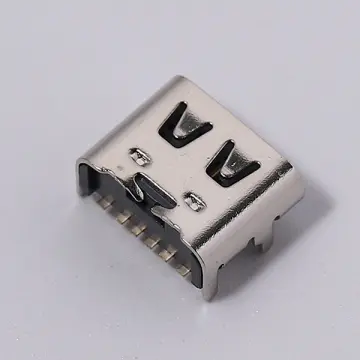

The shield can is a core component for electromagnetic compatibility in electronic devices, acting as an "invisible guardian" with excellent signal isolation. It bidirectionally blocks external stray signals (e.g., from base stations, industrial motors) to protect internal components (chips, sensors) from interference, while containing internal high-frequency waves to avoid disrupting nearby equipment—vital for densely packed systems.

Widely used in consumer electronics (smartphones shield radio frequency modules for stable signals), automotive electronics (protects EV radar from motor/battery interference), 5G base stations (reduces amplifier signal crosstalk), and medical devices (ensures accurate monitoring/MRI signals), it’s integral to diverse fields.

01

Material choice defines performance. Nickel silver (Cu-Ni-Zn alloy) leads for high-frequency shielding, offering 20%+ IACS conductivity and strong solderability—ideal for PCB mounting. Stainless steel, with strength and corrosion resistance, suits industrial/outdoor use; aluminum alloy, lightweight, serves aerospace. High-end models use multi-layer composites (metal plating + insulation) for balanced shielding and insulation.

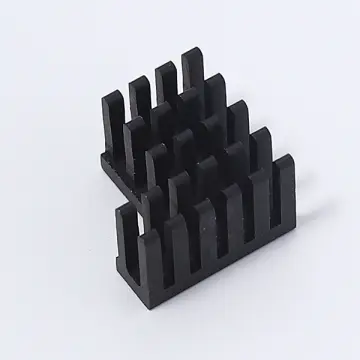

Structurally, one-piece cans (seamless, stamped) minimize wave leakage for small components. Combined types (base + cover, via buckles/screws) ease maintenance for frequently inspected modules. Precision 0.5-2mm ventilation holes balance heat dissipation (airflow) and shielding (electromagnetic "fences").

01

Manufactured via stamping (mass production, ±0.05mm precision), etching (fine patterns for high-density circuits), and surface treatments (nickel/gold plating for conductivity/oxidation resistance), shield cans are indispensable in modern electronics, ensuring safe, stable electromagnetic environments.