008613968780263

008613968780263

0102030405

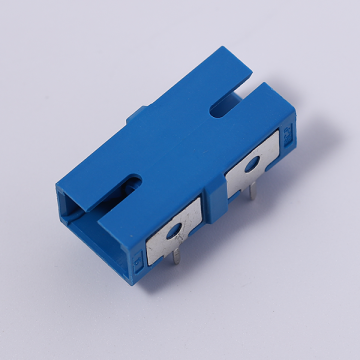

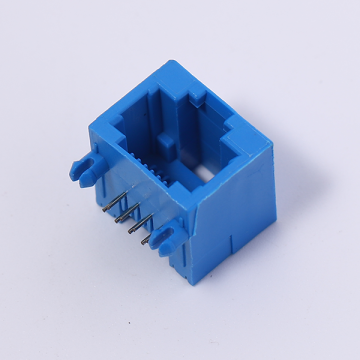

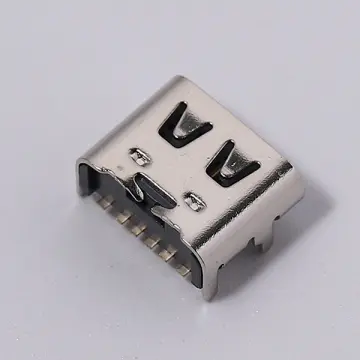

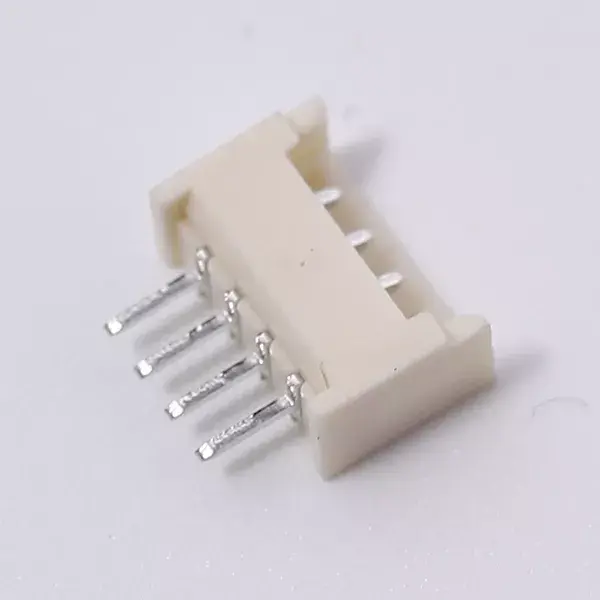

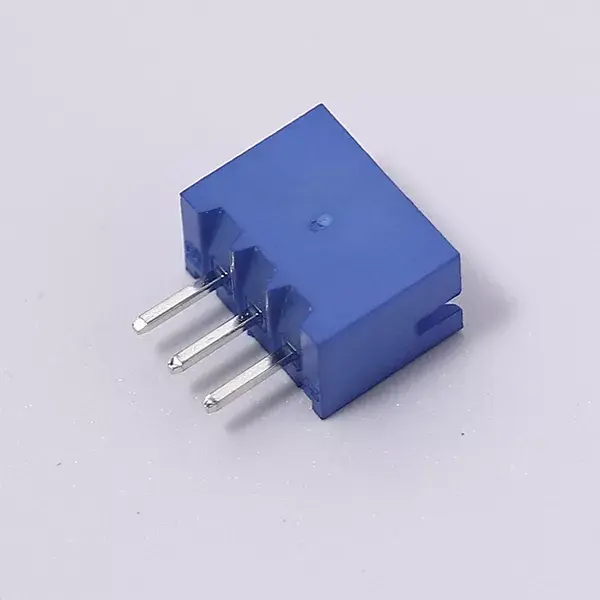

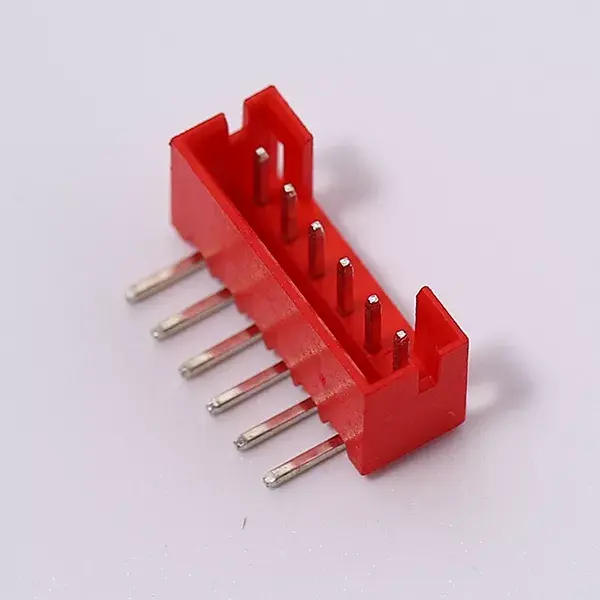

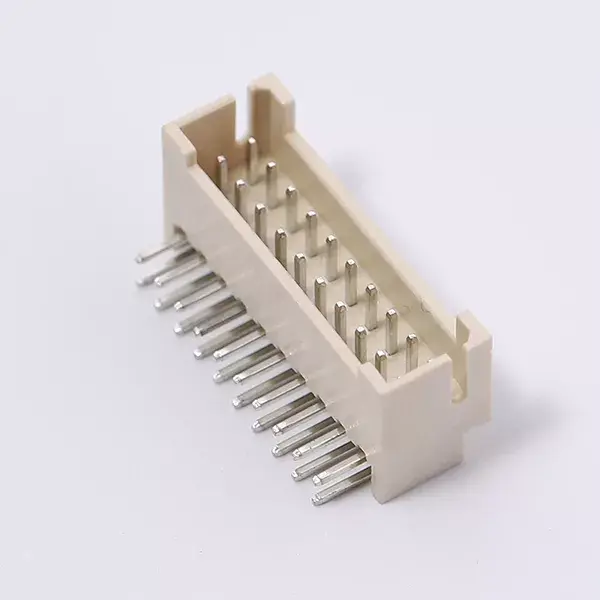

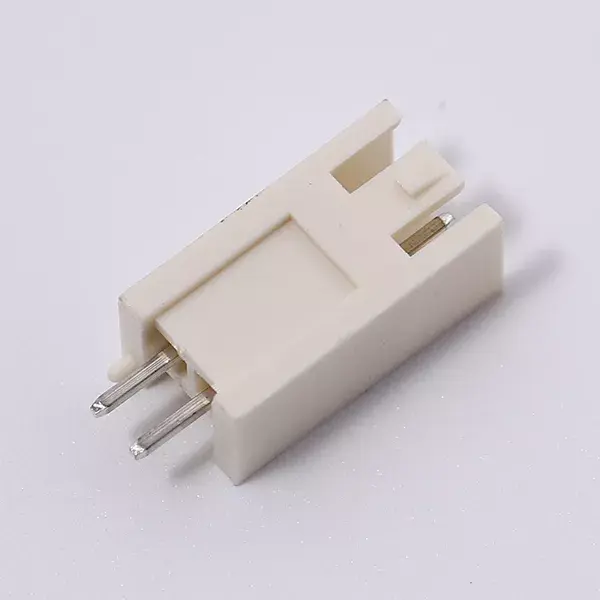

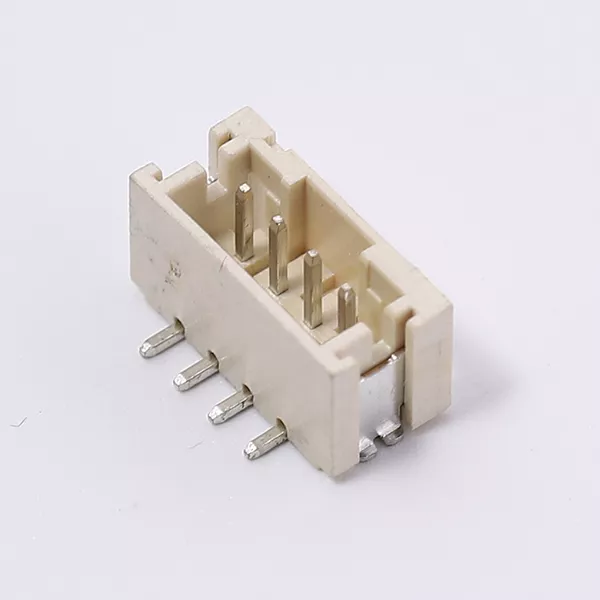

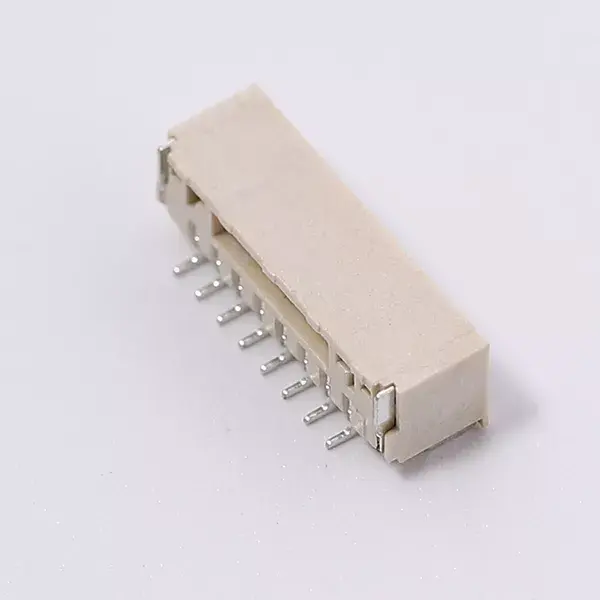

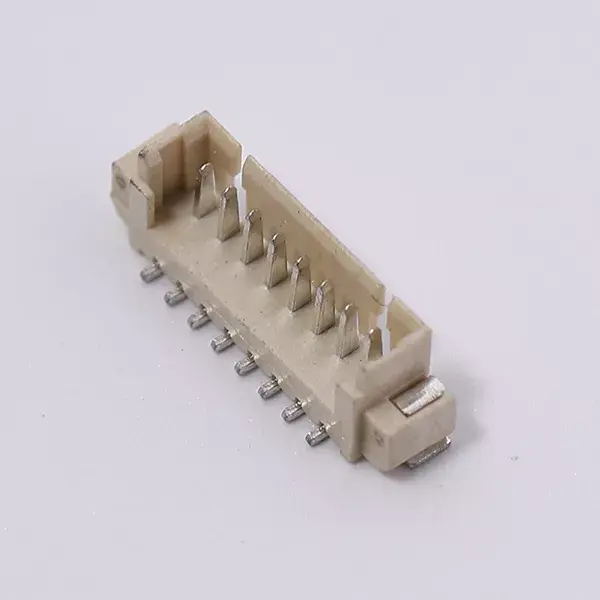

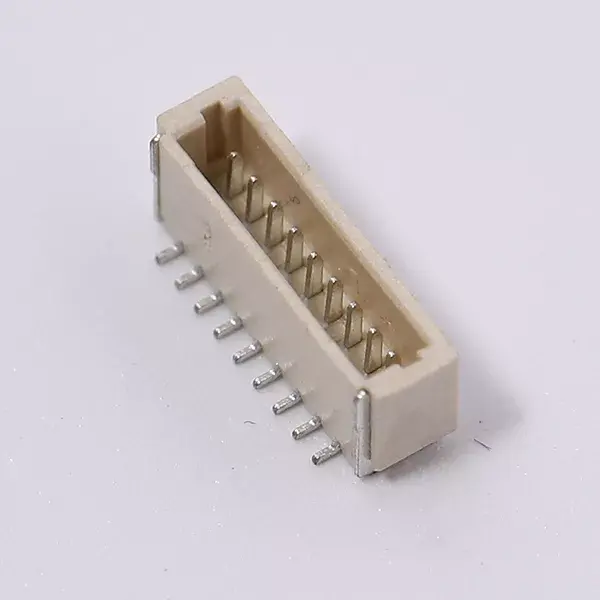

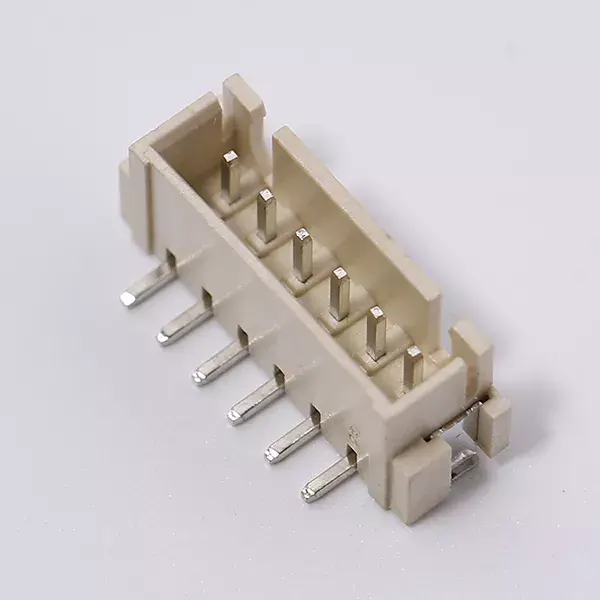

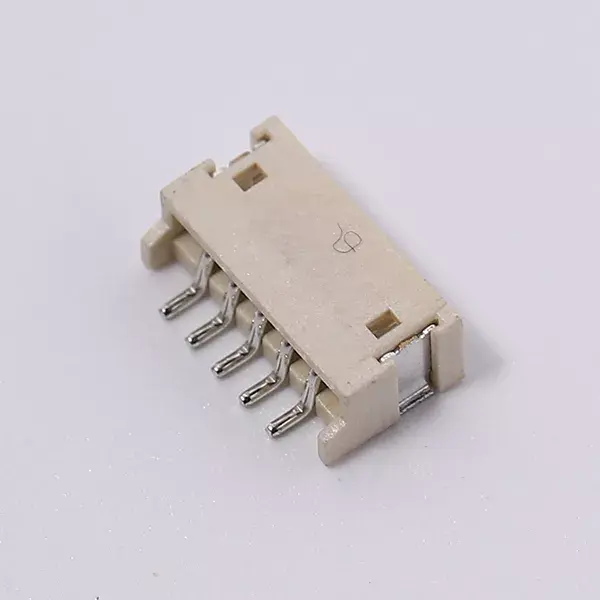

Pin Header Connector

01

Consumer Electronics

Home appliance control board: signal transmission for main control boards such as air conditioning and washing machines.

Digital devices: Connection between internal modules of routers and set-top boxes.

01

Industrial control

PLC module: signal and power interface for industrial automation equipment.

Sensor connection: Signal transmission for temperature and humidity sensors and photoelectric switches.

01

Automotive Electronics

Vehicle dashboard: The communication interface between the instrument panel and the ECU (electronic control unit).

Wire harness adapter: The transition connection between the wiring harness inside the vehicle and the circuit board.

01

Communication Devices

Base station module: low-frequency signal transmission and control line connection.

Fiber optic equipment: docking of auxiliary circuits with the motherboard.

01

Medical Equipment

Monitor module: Fixed interface for blood oxygen probe and ECG lead.

01

Electrical Performance

Signal transmission: Supports low-frequency signals (≤ 100MHz), suitable for control signal and power transmission.

Current carrying capacity: Single pin maximum current of 1-3A (depending on material and size), meeting conventional power supply requirements.

01

Machine Design

Standardization of spacing: Common spacing is 2.54mm (0.1 inch) and 1.27mm (high-density type).

Plug and unplug lifespan: typical value 500-1000 times (gold-plated pins can reach 3000 times).

Installation method: Through Hole Welding (THT) or Surface Mount Technology (SMT), compatible with automated production.

01

Materials and Reliability

Pin material: phosphor bronze (excellent conductivity), brass (low cost), surface gold-plated/tinned to prevent oxidation.

Base material: PA (nylon, high temperature resistant), PBT (chemical resistant).

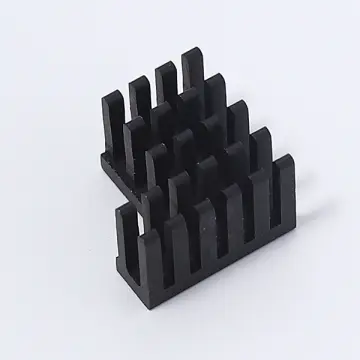

Environmental tolerance: working temperature -40 ℃~+105 ℃, some models support IP20 dust prevention.

01

Market Demand

Miniaturization: The demand for high-density connections is driving the popularity of 1.0mm pitch products.

Cost sensitive: The consumer electronics industry has a strong demand for low-cost, high-volume solutions.

01

Technical Upgrade Direction

High frequency expansion: Optimized pin design to support higher frequency signals (such as 10Gbps differential signals).

Environmental resistance: Develop high-temperature and corrosion-resistant materials (such as LCP base).

01

Industry Standards and Compliance

Safety certification: Must comply with UL, IEC 60664 (insulation performance) and other standards.

Environmental requirements: RoHS and REACH restrict the use of hazardous substances.

01

Product Positioning

As a basic connection solution, the needle socket connector is irreplaceable in low-cost and standardized scenarios, but it needs to compete with high-end connectors such as board to board and FPC to form differentiation.

01

Development Direction

Customized services: Provide color coding and anti misplacement design (such as keyway structure) to meet the needs of specific fields.

Automation adaptation: Optimize packaging forms (tape packaging) to improve SMT production line efficiency.

01

Marketing Strategy

Focus on the mid-range market: prioritize covering growth areas such as smart homes and industrial control.

Supply chain optimization: Reduce unit costs through large-scale production to cope with price competition.