008613968780263

008613968780263

0102030405

SRX24-035-Y7

01

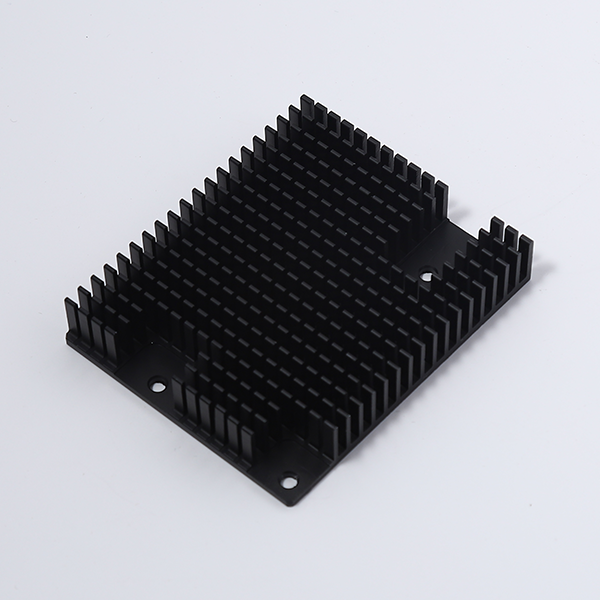

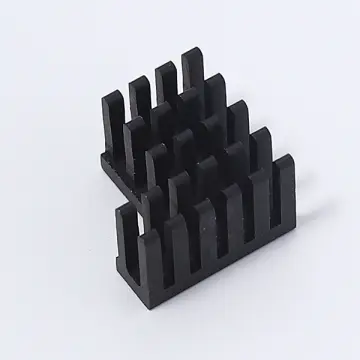

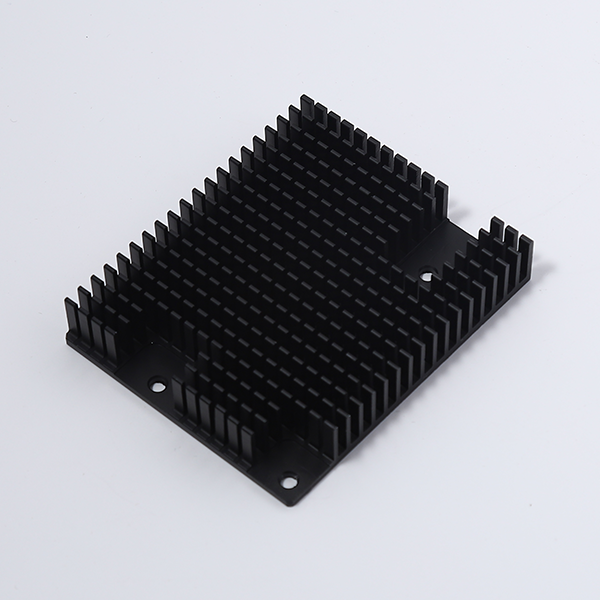

Aluminum profile radiators, with high-purity aluminum alloy as the core material, rely on precision extrusion molding technology to create multi-dimensional heat dissipation structures, and are core components in the modern industrial heat dissipation field. Their base material is selected from 6063 or 6061 series aluminum alloys. These alloys not only have excellent thermal conductivity of more than 200W/(m·K), but also have excellent mechanical processing performance. They can extrude complex fin shapes through molds at one time, avoiding thermal resistance loss caused by traditional welding processes.

The product structure design is highly targeted: the main body adopts an integrated "base material + fin" structure. The fin density can be set to 8-30 fins per inch according to heat dissipation requirements. Some high-end models extend the fin height to more than 150mm through secondary stretching technology. Combined with the fin thickness of 0.8-1.5mm, the heat dissipation area is maximized in a limited space. The surface treatment process is also sophisticated. After anodizing, an oxide film of 5-10μm is formed, which not only has a salt spray resistance of more than 500 hours, but also can be adapted to the visual needs of different industrial environments through coloring treatment; in some special scenarios, electrophoretic painting or chemical conversion film treatment can also be used to further improve corrosion resistance.

01

In terms of application fields, aluminum profile radiators cover multiple industries with their excellent performance. In the power electronics field, it is a key heat dissipation component for inverters and rectifiers. It adapts to IGBT modules through customized special-shaped structures to ensure that power devices operate stably in high-temperature environments. It has been widely used in new energy vehicle charging piles, photovoltaic inverters and other equipment; in the LED lighting industry, its lightweight characteristics (density only 2.7g/cm³) and rapid heat dissipation capacity perfectly match the needs of outdoor street lamps and industrial and mining lamps, which can control the working temperature of LED chips below 60℃, significantly extending the lamp life to more than 50,000 hours.

01

In the industrial automation field, equipment such as servo motors and PLC control cabinets rely on aluminum profile radiators to maintain stable working conditions, especially in high-temperature workshops such as metallurgy and textile. Their temperature resistance (-40℃ to 120℃) can ensure the continuous operation of the control system; in the communication equipment field, the RRU module of 5G base stations achieves efficient heat dissipation through compact aluminum profile radiators. With the forced convection of fans, it can control the core temperature of the module within 85℃ when the ambient temperature is 45℃, meeting the 24-hour uninterrupted operation requirements of the base station. In addition, in fields with high safety requirements such as medical equipment and rail transit, the non-volatile and anti-vibration characteristics of aluminum profile radiators also make them the preferred solution, providing a solid guarantee for the long-term and reliable operation of equipment.