008613968780263

008613968780263

0102030405

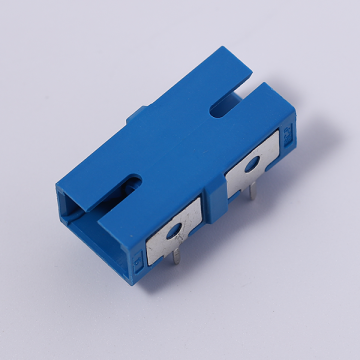

surface - mount gasket

01

Surface-mount gaskets are functional components specially designed for precision electronic devices and mechanical structures. With their unique surface-mount installation process and diverse material properties, they have become key elements in improving the stability and durability of equipment.

In terms of material selection, surface-mount gaskets cover a variety of elastic materials such as silicone rubber, EPDM, and polyurethane. Some high-end models also adopt a composite material structure - the surface layer is a wear-resistant polytetrafluoroethylene film, and the inner layer is high-elastic foam. This material combination can meet the sealing requirements in different scenarios and provide excellent buffering performance. It can withstand temperature changes from -40℃ to 120℃, and also has properties such as UV resistance and chemical corrosion resistance, making it suitable for various environments including indoor precision instruments and outdoor communication equipment.

01

Its surface-mount installation design is one of the core advantages. The back of the gasket is pre-coated with high-performance pressure-sensitive adhesive, which can be directly attached to the surface of various substrates such as metal, plastic, and ceramics without additional fasteners. This not only simplifies the assembly process but also avoids the problem of stress concentration caused by traditional screw fixation. The thickness of the gasket after installation is uniform, with an error controlled within ±0.05mm, which can ensure tight fit with the mating components and effectively block the intrusion of dust, water vapor, and tiny particles, with a protection level of up to IP65.

01

In terms of functions, surface-mount gaskets have three core values: first, they can absorb vibration energy through a compressible amount of 0.2-5mm, reducing component resonance during equipment operation, which is especially suitable for the shock absorption needs between PCB boards and casings; second, they block the conductive path between metal components by using the insulating properties of the material, preventing electrochemical corrosion; third, they fill the micro gaps on the contact surface, reduce sound wave transmission, and help the equipment meet lower noise standards.

In terms of specifications, surface-mount gaskets can be customized into various shapes such as round, square, and special-shaped according to needs. The minimum size can reach 3mm×3mm, and the maximum can support super large specifications of 1000mm×500mm, meeting the diversified assembly needs from micro sensors to large industrial control cabinets. In addition, by adjusting the material density, the hardness can be adjusted from 5 to 80 Shore A to adapt to the sealing requirements in different pressure environments.

Whether it is the shockproof of the motherboard of smart phones in the consumer electronics field or the sealing of battery packs in new energy vehicles, surface-mount gaskets, with their lightweight, easy installation, and multi-functional characteristics, have become indispensable supporting components in modern precision manufacturing.