008613968780263

008613968780263

0102030405

WYZ-A01-01

01

In the electronics field, die-cast housings have become core protective components for various precision devices due to their excellent comprehensive performance. Their applications cover numerous scenarios such as communication base stations, industrial control modules, smart home terminals, and medical electronic instruments. These housings are mostly made of ADC12 aluminum alloy or A380 die-cast aluminum alloy as raw materials and are formed in one go through high-pressure die-casting processes. They can not only meet the strict requirements of electronic devices for structural strength but also provide a stable electromagnetic shielding environment for internal sensitive components through the metal properties of the material itself.

01

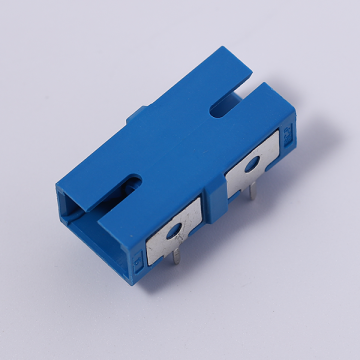

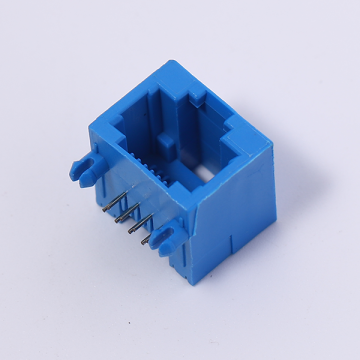

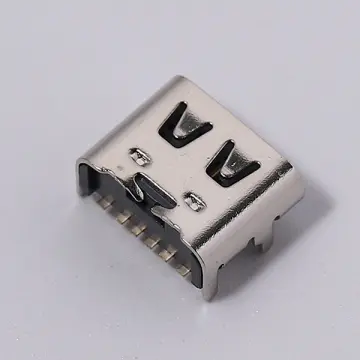

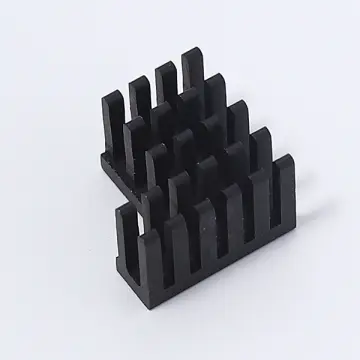

In terms of structural design, die-cast housings in the electronics field show strong adaptability. To meet the high-density heat dissipation requirements of 5G communication modules, the housings can be integrally formed with multiple sets of heat dissipation fins. Combined with the design of internal diversion grooves, the heat dissipation efficiency is more than 40% higher than that of traditional stamping housings. For the complex interface layout of industrial control equipment, the die-casting process can accurately achieve dimensional tolerances of 0.1mm level, ensuring the seamless connection between interfaces such as USB and HDMI and the housing, and avoiding signal attenuation caused by assembly gaps. In addition, the surface of the housing can be treated with processes such as anodizing and electrophoretic coating to form a protective film with a thickness of 5-10μm, which can still maintain stable insulation performance and corrosion resistance in the working environment of -40℃ to 85℃.

01

In terms of functional integration, modern electronic die-cast housings have broken through the limitation of single protection. For example, in smart home central control equipment, the housing can have a built-in EMI shielding compartment to physically isolate the radio frequency module from the power module, reducing signal interference. The die-cast housing of medical electronic equipment achieves IP67 dustproof and waterproof standards through the design of a sealed structure, meeting the disinfection needs of special environments such as operating rooms. At the same time, the lightweight characteristic (the density of aluminum alloy is only 1/3 of that of steel) allows the weight of the housing of portable electronic equipment to be controlled within 100g, taking into account both durability and portability.

With the development of electronic devices towards miniaturization and integration, die-cast housings are evolving towards multi-cavity and thin-walled directions. Housings produced by vacuum die-casting technology can have a wall thickness as thin as 1.5mm while maintaining structural integrity, saving more than 30% of the installation space for internal components. This advantage of "exchanging space for performance" makes it the preferred housing solution for emerging electronic devices such as millimeter-wave radars and laser sensors, continuously promoting technological innovation in the electronic manufacturing field.